packaging machines india

our company

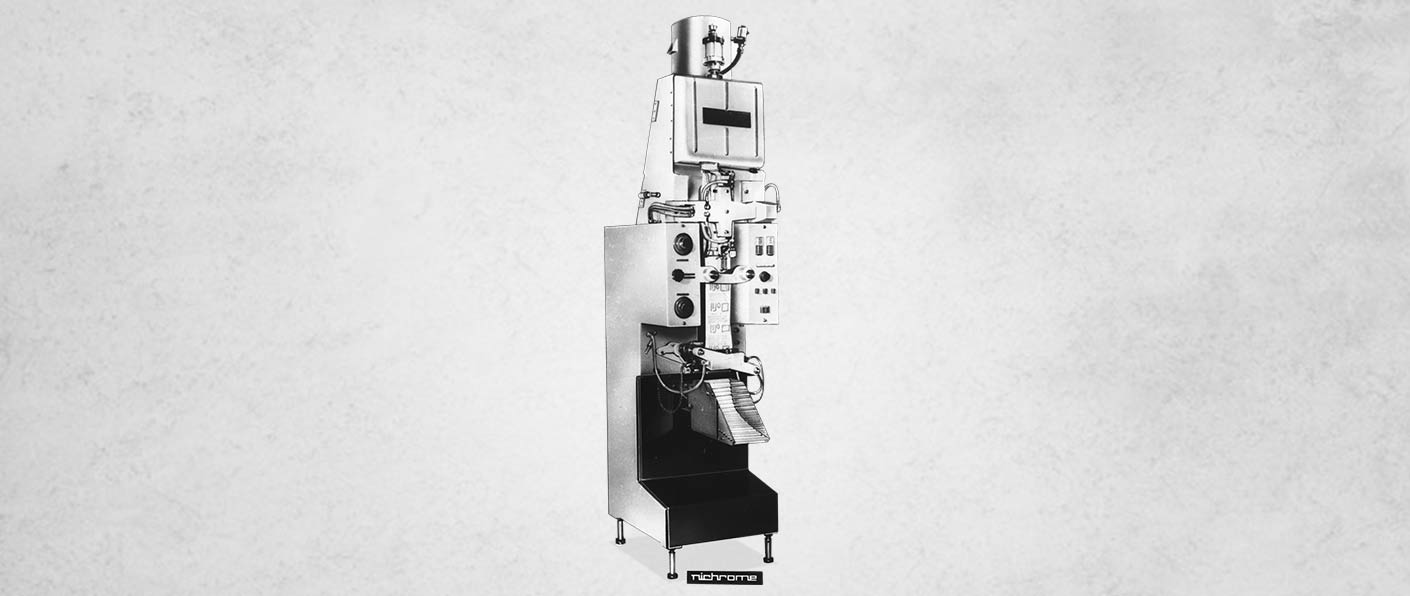

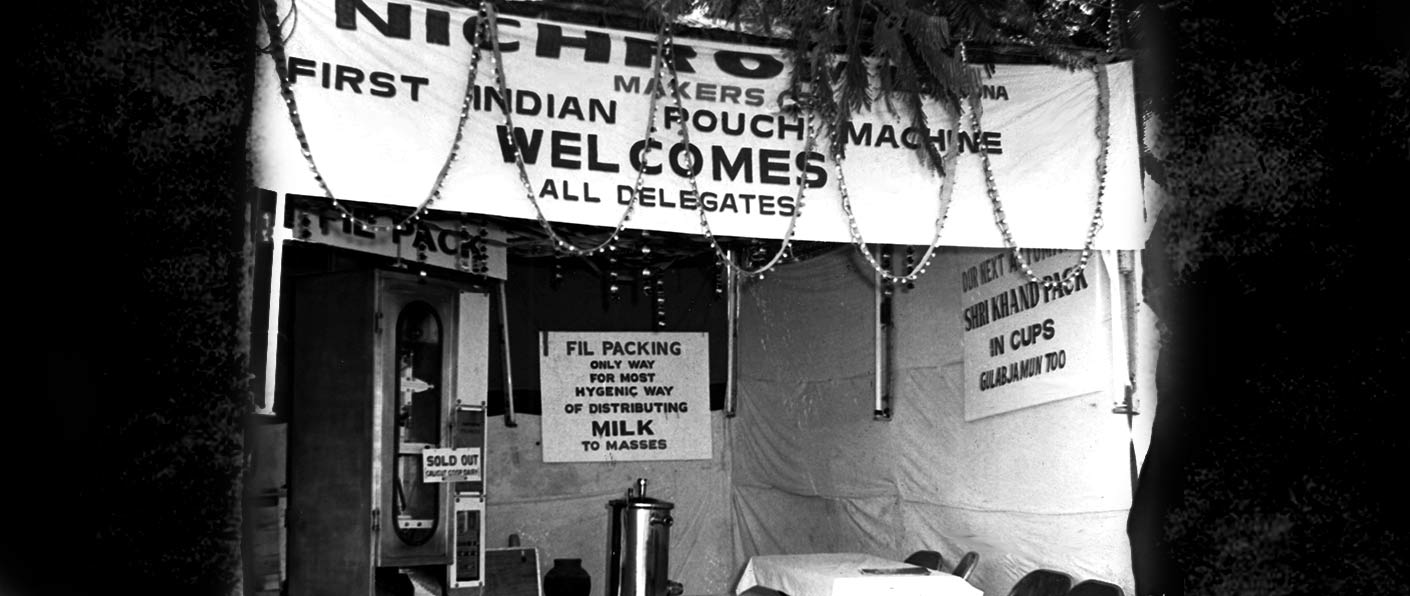

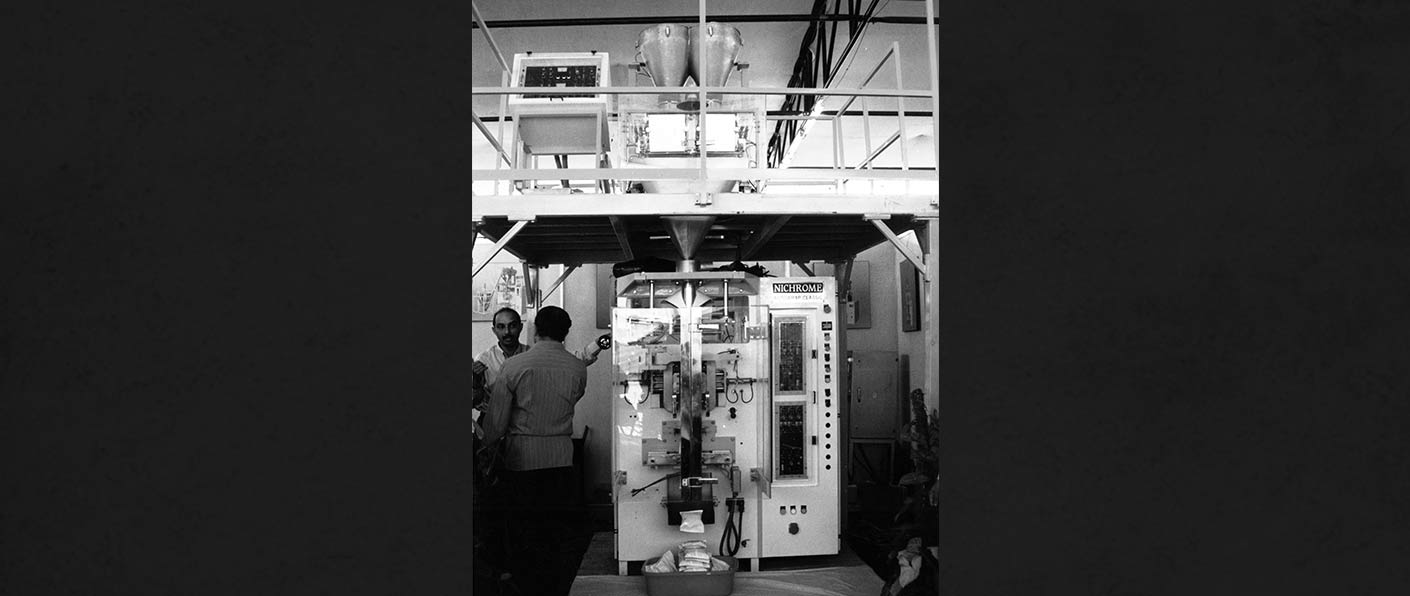

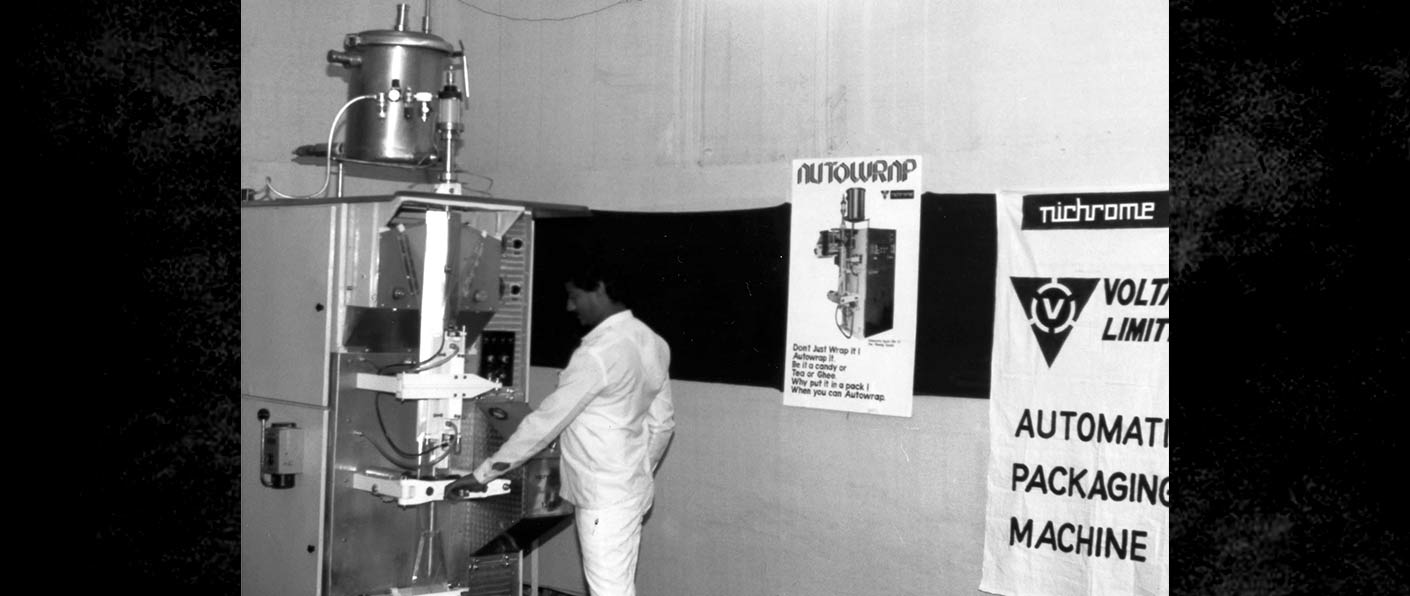

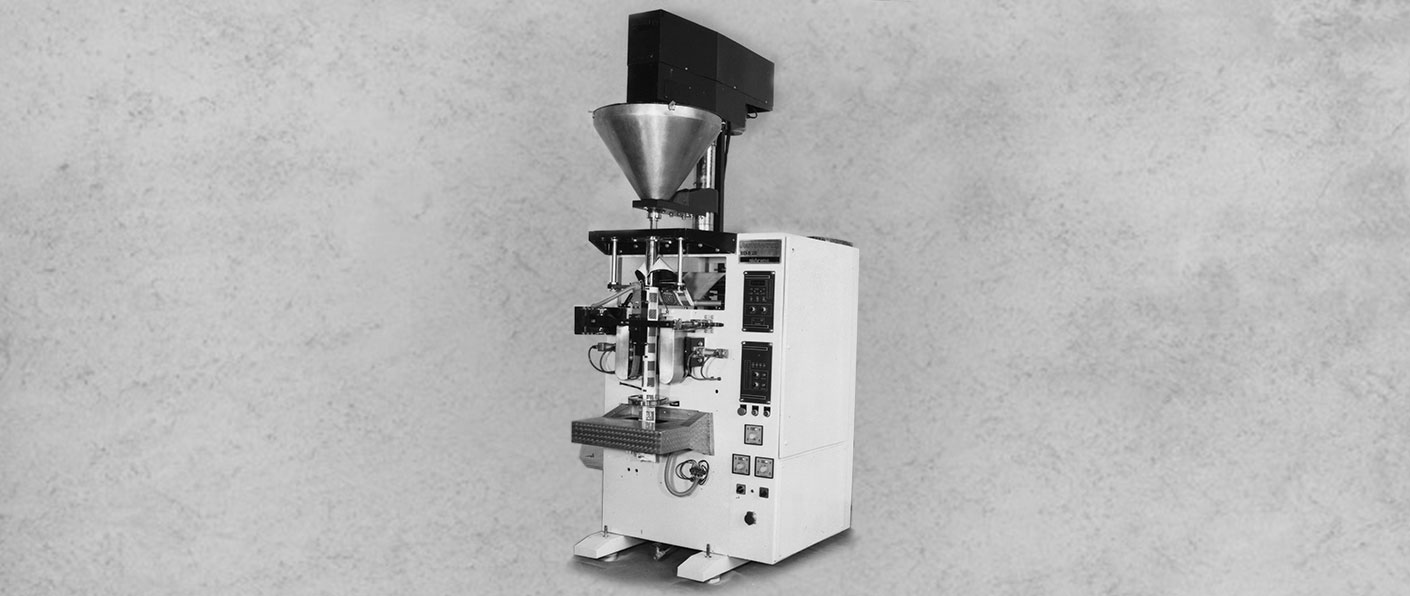

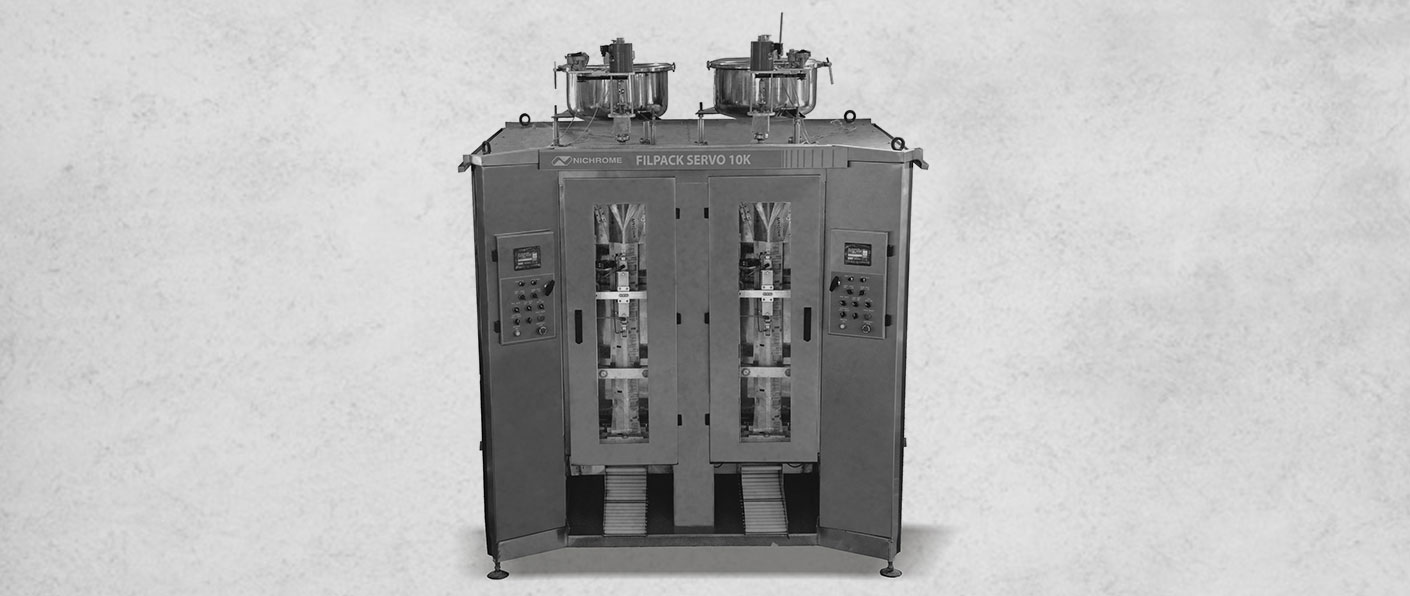

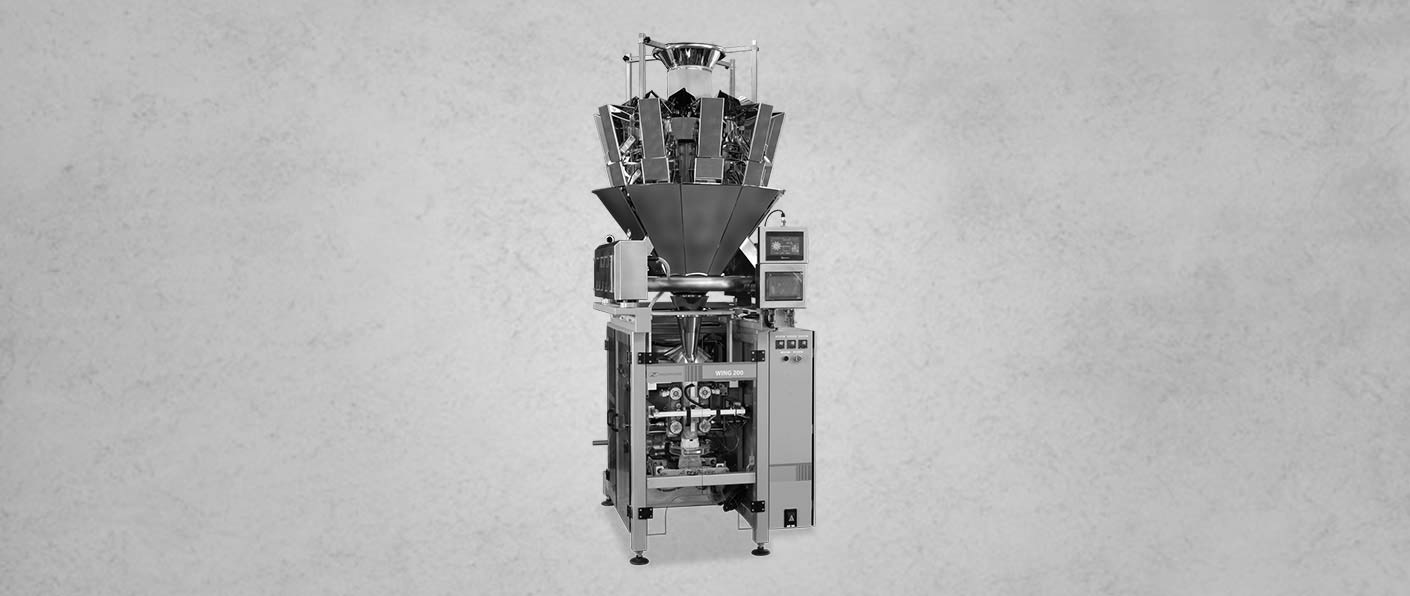

Since we developed India's first indigenous milk packaging machine in 1977, we have been at the forefront of next-generation packaging technologies; a brand trusted for its rich legacy of pioneering innovation, extensive domain knowledge and manufacturing competency in packaging systems.

For enterprises big and small, for applications existing and emerging, we offer infinite possibilities in integrated, automated packaging solutions - as we partner with customers through the complete lifecycle, offering application-specific solutions, backed by dependable service and support.

Based in Pune, India, our sales & service network spans India and the world. We have presence in 50+ countries and more than 11000+ successful installations worldwide.

INFINITE POSSIBILITIES

For startups, medium sized businesses or large MNCs, for existing or emerging applications, Nichrome offers infinite possibilities in packaging solutions. That too, with one-stop convenience.

With our strong thrust on R&D, we partner with customers, study their market and specific application, and innovate integrated solutions that deliver relevant advantages.

It could be a small variation in a pouch format or customization of an existing machine; a pro-actively developed filling system or consultancy & system design for a complete packaging plant - Nichrome has the expertise, capabilities and innovation to transform productivity and enrich customer relationships in endless ways.

OUR BRAND

Values

INTEGRITY

Being reliable and honest with transparent interactions both internally and externally; winning customer trust by being consistent and committed

FORWARD-THINKING

Thinking ahead of the market, challenging the status quo, trying new things and ideating to make a difference

PROFICIENCY

Continuously improving at individual and team performance levels, strengthening customer relationships, building expertise and applying thoroughness in every detail

RESPECT

To customers, partners, suppliers and fellow team members; embracing diversity and being responsible in communication and delivery

INNOVATION

Pursuing research & development, bringing a fresh perspective and exploring new technologies and avenues to find more effective solutions

Leadership

Mr. S.V. Joshi, Chairman

A visionary leader and industry pioneer, Mr. S.V. Joshi took the helm of Nichrome in 1974, charting a new course for the company into the realm of equipment manufacturing and the packaging industry. His entrepreneurial spirit and commitment to innovation continue to shape the company's vision.

Ms. Mrunal Joshi, Vice Chairperson and CEO

With over two decades of leadership experience and a deep understanding of market dynamics, Ms. Joshi started her journey with us in 2001. Her marketing expertise and strategic vision have been instrumental in strengthening the company's brand and expanding its reach. In 2013, Mrunal took on responsibility for Nichrome's overall business growth, successfully steering the company's transformation to a complete ‘Packaging Automation Solutions’ partner for various industries. As CEO, she continues to lead the company towards a future of innovation and sustainable packaging solutions. Her leadership is marked by a deep commitment to customer satisfaction, employee empowerment, and technological advancement. Her excellent people skills and collaborative approach foster a strong and motivated team, driving its continued progress.

Ms. Mrunal Joshi, Vice Chairperson and CEO

With over two decades of leadership experience and a deep understanding of market dynamics, Ms. Joshi started her journey with us in 2001. Her marketing expertise and strategic vision have been instrumental in strengthening the company's brand and expanding its reach. In 2013, Mrunal took on responsibility for Nichrome's overall business growth, successfully steering the company's transformation to a complete ‘Packaging Automation Solutions’ partner for various industries. As CEO, she continues to lead the company towards a future of innovation and sustainable packaging solutions. Her leadership is marked by a deep commitment to customer satisfaction, employee empowerment, and technological advancement. Her excellent people skills and collaborative approach foster a strong and motivated team, driving its continued progress.

Maithilee Joshi | Executive Director - Strategy

Maithilee brings a unique blend of design thinking, strategic business acumen and youthful enthusiasm to her role. She has been instrumental in driving innovation at Nichrome, particularly in developing end-of-line packaging solutions and automation technologies. She currently spearheads the development of sustainable, next-generation packaging solutions and contributes to company's overall growth strategy.

Parag Patwardhan, VP - Sales and Marketing

Parag Patwardhan heads the Global Sales and Marketing function at Nichrome India. He is responsible for developing the strategic sales plans based on company goals to promote sales growth and customer satisfaction for the organization. Highly skilled with 25 years’ experience in handling sales & marketing for global conglomerates. He is an adaptable leader with the ability to work independently, and develop opportunities that further establish organizational goals.

Legacy

CSR

TMNP - Nira CSR Project by Nichrome India Ltd. 2022-2023

"Nira" stands for Nurturing Intelligent Rural Aspirants.

Nichrome which stands for its innovation in packaging solutions, collaborates with the Tribal Mensa Nurturing Program, a chapter of Mensa India for underprivileged gifted. "Nira" is a unique CSR program launched in 2022 -2023 with an aim" to identify, nurture and nourish underprivileged gifted children for the nation building.

View More

“Blood donation is the biggest donation”, is a well-known proverb.

Nichrome regularly organises Blood Donation Camps which receive great response from all Nichromians as well as the people from Wing.

Nichrome donated a Computer to the “School for the Deaf & Dumb", Bhor to help students gain basic knowledge of computers. The school has 79 students, ranging from Nursery to 12th Standard.

For the toddlers at the “School for the Deaf & Dumb", Bhor, we donated two Playground Slides to enjoy during their play time. As Nichromians, we are happy to spread smiles on their little faces!

A 3-day Camp - “Gao Sukhi Tar Desh Sukhi” was organized at Rameshwar Vidyalay, Wing. Some of the topics discussed included water harvesting, preparation of a village map, careers and employment which can be created in the village, etc.

Conducted through “Swaroop-Vardhini”, the camp was attended by students, gram panchayat members, social leaders, the village school principal and Nichrome representatives.

We organized a ‘Lecture series’ for career development under ‘Disha’ Project through Jnana Prabodhini. The inaugural lecture was on Personality Development by Dr. Anagha Lawlekar.

Three schools participated: Rameshwar Vidyalaya (Wing), Kranti Jyoti School (Naigaon), and Pachkrushi School (Loham).

We organized another ‘Lecture series’ under ‘Disha’ Project through Jnana Prabodhini. The Series covered different subjects related to career development for senior students of Rameshwar Vidyalaya (Wing), Krantijyoti Savitribai Phule Smarak, Naygaon and Panchkroshi School, Lohom.

A third lecture ‘Notes making and memory techniques' by Mr. Deepak Gupte helped students of Rameshwar Vidyalaya (Wing), Krantijyoti Savitribai Phule Smarak, Naigaon and Panchkroshi School, Lohom.

Nichrome donated Rs. 1 Lac to ‘Vanwasi Kalyan Ashram’, Bhor for ‘Bunk Beds’ for the children of the Ashram. The ashram is home to around 60 children from remote adivasi villages.

Food

- Snacks & Namkeen Packaging Machine

- Ready-to-Eat Food Packaging Machine

- Grains & Seeds Packaging Machine

- Milk & liquids Packaging Machine

- Powder Packaging Machine

- Spice Packaging Machine

- Coffee Packaging Machine

- Sugar Packaging Machine

- Oil Packaging Machine

- Salt Packaging Machine

- Tea Packaging Machine