Efficient Flexiwrap Strip Folding: Nichrome Packaging in India

The Indian FMCG and food industries are evolving at lightning speed. Increasing consumer demands for hygiene, uniformity, and quick delivery have transformed packaging from a basic operational requirement into a key differentiator. From chocolate bars to pharmaceutical tablets, sachets, and beauty strips, manufacturers now recognize that manual or semi-automatic packaging processes are no longer viable; they’re labor-intensive, time-consuming, and prone to inconsistency.

For manufacturers seeking efficiency and consistency, Nichrome offers a comprehensive range of automated packaging systems built on decades of trust. Nichrome’s strip folding and associated packaging machines provide accuracy, speed, and automation. From a flexiwrap strip folder to a flow wrap machine or a vertical form fill seal machine, Nichrome provides solutions that enhance packaging operations in various industries.

Why Automation Matters for Strip Folding in India

India’s manufacturing industries are dynamic and competitive. Rapid urbanization, increased disposable incomes, and shifting consumer trends put pressures on manufacturers to meet:

- Hygiene while processing sensitive products like medicines or chocolates.

- Less human error and decreased product wastage.

- Increase production in cycles to suit seasonal or market demand surges.

- Offer flexible packaging sizes, ranging from strips to pouches, cartons, or bottles.

Manual strip folding is slow, irregular, and subject to contamination. Semi-automatic equipment brings some increase in speed but is still limited in precision and output. Automated strip folding systems and horizontal flow wrap machines address these issues by offering consistent folding, sealing, and packaging at high rates of speed.

Nichrome’s Strip Folding Solutions

Nichrome offers access to internationally acclaimed systems designed to suit the Indian market. Here’s a glance at some of the most relevant technologies:

1. Flexiwrap Strip Folder

Nichrome’s flexiwrap strip folder is best suited for FMCG, food, and nutraceutical categories in which items are packaged in sachets or pouch strips. It integrates speed and accuracy to deliver neatly folded laddis (strings of pouches) that are subsequently ready for secondary packaging.

Key Features:

- Suitable for sachets, pouch strips, and laddi-form products.

- High-speed folding with minimal product damage.

- Smooth integration with flow wrap machines for uninterrupted production.

- PLC control for repeatable and accurate operations.

- Simple changeover and versatile for both small-scale and high-output production lines.

This automatic packaging machine minimizes manual handling, maintaining better hygiene while delivering consistently aligned strips for secondary packing.

2. Flow Wrap Machines

Flow wrap machines are part of Nichrome’s secondary packaging solutions. Once pouch strips or collated packs are formed, they are wrapped for distribution and retail. Nichrome offers:

- Horizontal flow wrap machines (Flexiwrap 700) for biscuits, chocolates, bakery products, and similar products.

- Automatic flow wrap systems (Flexiwrap ST) that collate sachets or pouches from a VFFS line and flow wrap them into distributor packs or retail-ready packs.

Key benefits:

- Consistent quality high-speed wrapping.

- Blanket integration with strip folder and pouch collation equipment.

- Less wastage and improved visual presentation for retail display.

For instance, a sachet producer can take laddis (pouch strips) from a strip folder and insert them directly into a horizontal flow wrap machine, ensuring smooth production and hygiene controls.

3. Vertical Form Fill Seal (VFFS) Machines

Nichrome’s Vertical Form Fill Seal (VFFS) machines constitute the initial stage in the strip folding system. They fill products into sachets, which are then fed to the strip folder for striping into laddis. The VFFS machine:

- Handles various products such as powders, granules, liquids, pastes, and snack foods.

- Provides flexibility in pouch dimensions and several sealing types like CSPP, 3-side seal, 4-side seal, and gusseted pouches.

- Can be integrated with flexiwrap strip folders, flow wrap machines, as well as other automation systems for overall packaging solutions.

Upon incorporating a VFFS machine into a strip folder, manufacturers automatically create the process from pouch formation to strip arrangement, cutting down on manual handling, improving hygiene, and increasing efficiency.

4. Secondary Packaging Solutions

Following primary packaging, products often require secondary packaging for logistics and retail display. Nichrome provides end-to-end solutions such as:

- Carton packing strip machines to pack folded strips into cartons.

- Secondary packaging machines such as case packers and end-of-line equipment for bulk shipments.

- Integration with pouch packing machines for multi-strip packaging.

Key benefits:

- Maintains products secure during transit.

- Allows for efficient shipment preparation with low manual handling.

- Works seamlessly with upstream folding and wrapping equipment for a complete packaging line.

Advantages of Nichrome Strip Folding Systems

Investing in Nichrome strip folding machines and systems in India has the following advantages:

1. Accuracy & Consistency

Whether it is pharmaceutical tablets, chocolate strips, or nutraceutical sachets, Nichrome machines provide accurate folds and packaging every time. This minimizes product giveaway and gives better presentation.

2. Safety & Hygiene

The equipment is constructed with pharmaceutical-grade and food-grade stainless steel parts. Enclosed systems and minimized manual handling ensure product cleanliness and industry standard compliance.

3. Flexibility

Equipment such as the flow wrap machine and the VFFS machine accommodates various product configurations, from pouches and strips to cartons, with fast switchovers between product lines.

4. Scalability

From small drug labs to giant confectionery manufacturing plants, Nichrome offers automatic packaging machines, small flow wrap machines, and industrial-scale horizontal flow wrap machines according to production needs.

5. Automation & Control

Advanced PLCs, touch-screen HMIs, and safety interlocks make the machines easy to use and safe, with reduced downtime.

6. Local Support in India

With the extensive coverage of Nichrome all over India, the manufacturers benefit from local service, spare part availability, and operator training. This provides for uninterrupted operation and long-term stability.

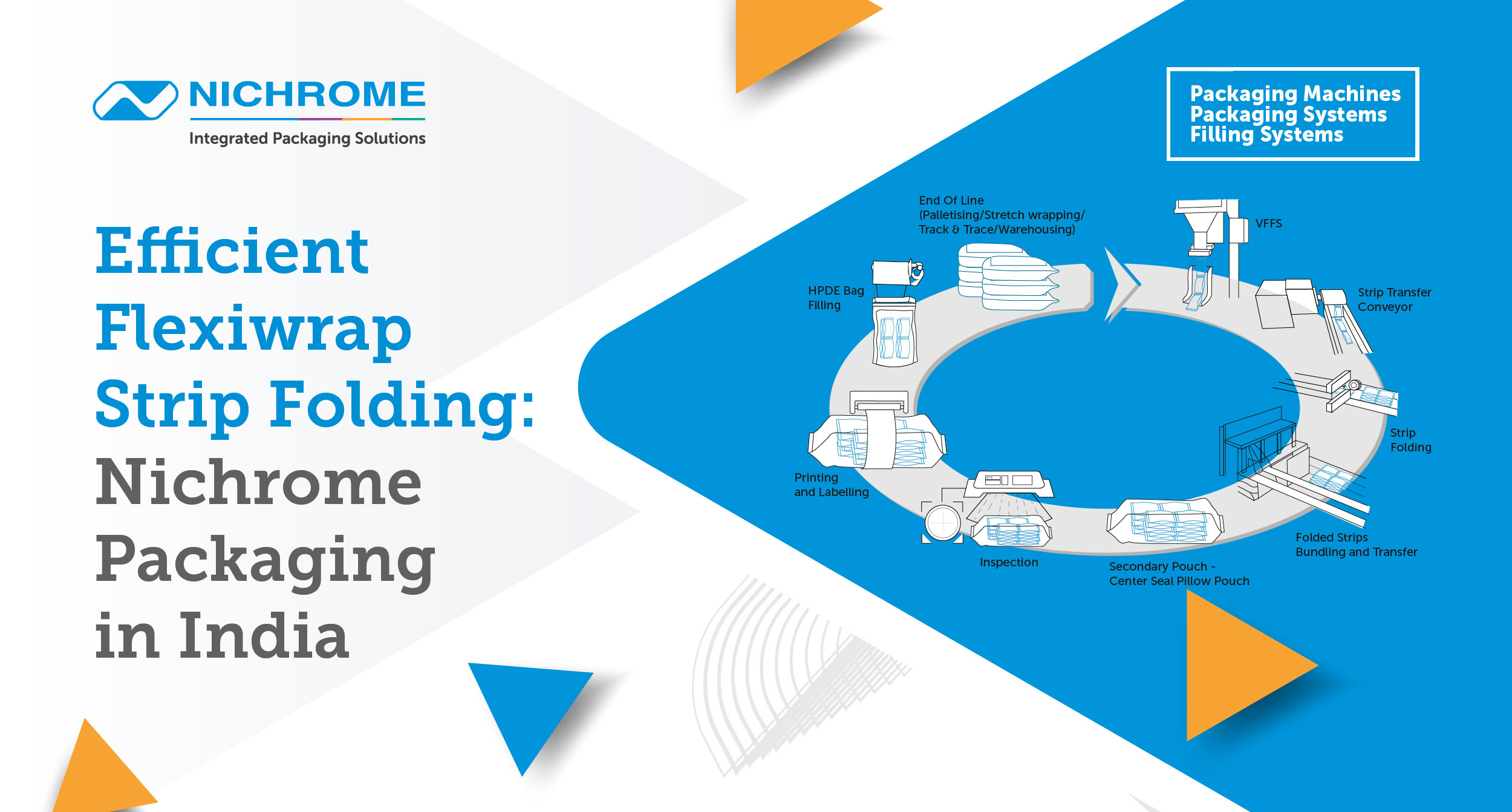

A Complete Strip Folding Line

Following is an illustration of a complete strip folding and packaging line for the manufacturers:

1. Strip Folding Stage: Automatic strip machine folds tablets, chocolates, or other products in an efficient manner.

2. Initial Packaging Stage: Folded strips are inserted in a flow wrapping machine (mini or horizontal) or VFFS packaging machine for solo pouch packing.

3 .Secondary Packaging Stage: Products are packed into cartons on carton packing strip machines or secondary packaging machines.

4. End-of-Line Equipment: Case erectors, palletizers, and end of line packaging equipment simplify the shipping process.

This combined system reduces labour-intensiveness, preserves hygiene, and provides consistent, high-quality packaging.

Conclusion

For Indian manufacturers, strip folding and packaging solutions are strategic investments. Manual folding and semi-automatic systems are unable to catch up to the speed, accuracy, and market hygiene standards of today’s market.

With Nichrome’s Flexiwrap strip folder, Flexiwrap 700 and Flexiwrap ST – flow wrapping machines, carton packing strip machines, and end-of-line packaging equipment, companies can:

- Guarantee consistent and precise folding and packaging.

- Keep processes hygienic and minimize risk of contamination.

- Increase production scale with efficiency.

- Realize cost savings through automation and lower wastage.

Whether it is a mini flow wrap machine

for small volume batches or a complete industrial horizontal flow wrap machine

line with integration of secondary packaging machines, Nichrome’s solutions

enable manufacturers to attain efficiency, quality, and market readiness.

By opting for Nichrome, Indian enterprises are

investing in reliability, velocity, and expansion. The future of strip folding

and packaging in India is efficient, hygienic, and automated, and Nichrome is

leading the way

0 comment