How Nichrome Helps in Improving Snack & Food Safety with its Advanced Snack Packaging Machines

In the dynamic world of snack production, the importance of maintaining food safety while ensuring efficiency cannot be overstated. Nichrome, a leading food packaging machine manufacturer in India has consistently led the way in improving snack packaging with its advanced technology machines. Among its standout innovations is our Sprint 250 Snack Pack machine, a testament to the company’s commitment to excellence in snack food packaging.

-

Elevating Food Safety Standards

Food safety is a paramount concern in the snack industry. Our advanced snack packaging machines are designed with this in mind, incorporating features that ensure products are not only attractively packaged but also meet the highest standards of food safety. Our automatic snack packaging machines, for example, are engineered to minimize human contact with the food product, drastically reducing the risk of contamination and preserving the freshness and quality of the snack inside.

Advantages of Using Nichrome’s Snack Packaging Machines

- Enhanced Efficiency and Productivity:

Our snack packaging machines are engineered for high-speed packaging, significantly boosting productivity. With features like automatic feeding, weighing, and packing, these pouch filling machines minimize manual intervention, thereby speeding up the production line and enabling manufacturers to meet larger orders more efficiently.

- Superior Packaging Quality:

Quality is paramount in food packaging, and our automatic snack packaging machines deliver on this front. Our machines ensure consistent quality in sealing, which extends the shelf life of snacks by protecting them from air, moisture, and contaminants. The precision in filling and sealing helps maintain the freshness and flavor of the snacks, making them appealing to consumers.

- Versatility in Packaging Options:

One of the standout features of our snack food packaging machines is their versatility. They can handle a wide range of snack types, from chips and nuts to candies and cookies, and are capable of packaging in various formats such as pouches, sachets, and bags. This versatility allows snack producers to use a single machine for multiple products, adapting to market trends and consumer preferences with ease.

- Cost-Effectiveness:

By automating the packaging process, our snack packaging machines reduce labor costs and minimize waste through precise filling and packaging. This cost-effectiveness is a significant advantage for snack manufacturers looking to optimize their operations and increase profitability.

- Advanced Technology Integration:

We incorporate the latest technology in our food packaging machines, including touch screen interfaces for ease of use, programmable settings for quick changeovers, and advanced diagnostics for troubleshooting. This integration of technology enhances operational efficiency and reliability.

-

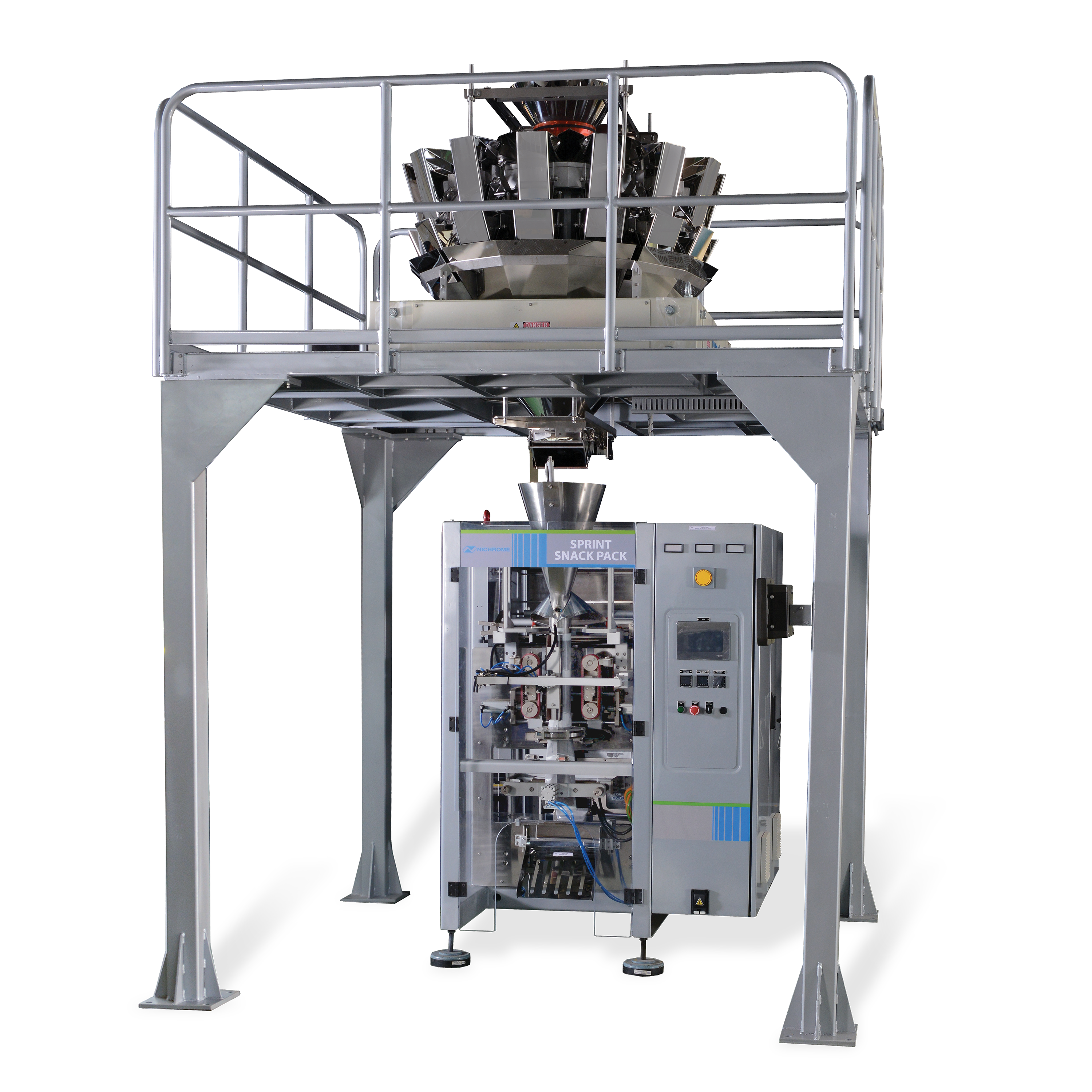

Sprint 250 Snack Pack: A Game Changer for Snack Industry

Our Sprint 250 Snack Pack machine epitomizes innovation in the world of snack food packaging machines. As an automatic packaging machine, it is equipped with cutting-edge technology that allows for precise weight control, ensuring that each package contains an accurate amount of product. This level of precision is crucial for maintaining consumer trust and satisfaction.

Moreover, the versatility of our Snack Pack machine is unmatched. Capable of handling a wide range of snack products, from crispy chips to delicate chocolates, it exemplifies the adaptability required in today’s fast-paced market. This sachet packaging machine and pouch filling capabilities makes it an invaluable asset for manufacturers looking to offer a variety of packaging options to their customers.

-

Conclusion

Our contribution to improving snack and food safety through its advanced packaging solutions is undeniable. The Sprint 250 Snack Pack machine, along with our comprehensive range of food packaging machines, snack packaging machines, and automatic packaging solutions, stands as a beacon of innovation and reliability in the industry. By prioritizing safety, efficiency, versatility, and sustainability, we continue to set new standards, ensuring that snack manufacturers can meet the demands of the modern consumer with confidence and ease.

0 comment