Bulk Bag Filling for Sugar Common Challenges and Packaging Solutions

In the sugar packaging industry, efficiency, accuracy, and consistency are paramount. However, several challenges can arise during the bulk bag filling process. The sugar industry is characterized by high-volume production and distribution, demanding integrated packaging solutions that can handle massive quantities of sugar while maintaining consistent filling levels and product quality. Bulk bag filling has emerged as a preferred method for packaging sugar due to its efficiency, convenience, and cost-effectiveness.

Bulk bag filling machines are specifically designed to handle the unique properties of sugar packaging, such as its granular form, varying densities, and moisture content. These machines employ precise weighing systems to ensure accurate filling levels and consistent weights in each bag. With our advanced technology and automation, bulk bag filling machines can significantly improve packaging speed, efficiency, and productivity in the sugar industry.

1. Ensuring Accuracy and Efficiency

One of the primary challenges in bulk bag filling for sugar is achieving accuracy and efficiency in the packaging process. Manual bag filling systems can be time-consuming and prone to errors. However, Nichrome’s bulk bag filling machine addresses this challenge by providing automated and precise filling capabilities. This sugar packaging machine enables high-speed filling of bulk bags, ensuring consistent and accurate weight measurements while optimizing productivity.

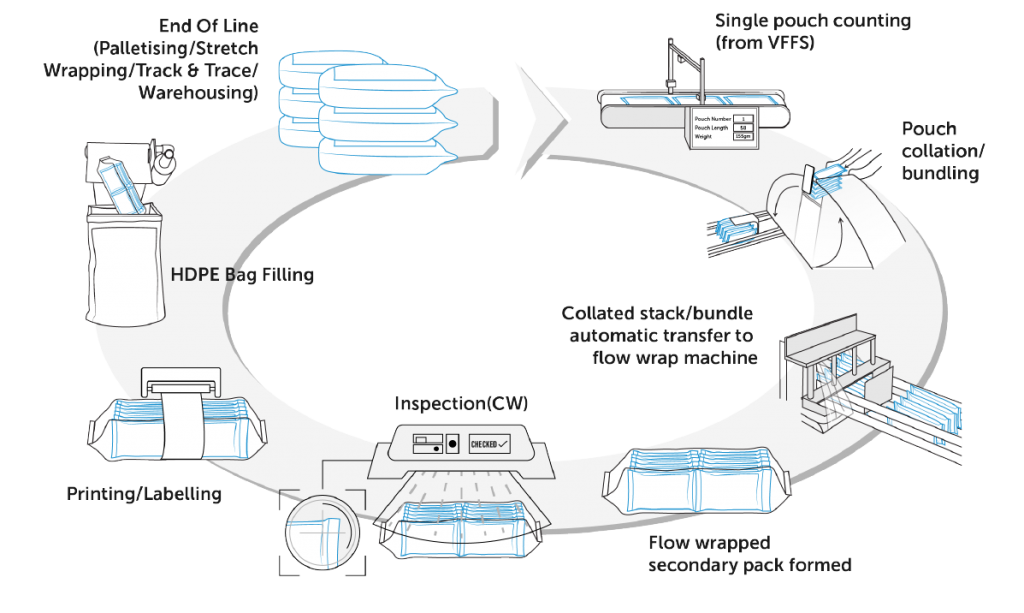

2. Secondary Packaging and Safety

Another significant challenge in sugar packaging is the need for secondary packaging and ensuring product safety. Bulk bagging systems often require additional processes such as palletizing and stretch wrapping to secure the filled bags. Nichrome’s integrated packaging solutions have come to the rescue here, offering secondary packaging machines that seamlessly complement the bulk bag filling machine. These secondary packaging solutions, such as palletizers and stretch wrapping machines, ensure proper handling, stability, and protection of the filled bags during storage and transportation.

3. Customization and Adaptability

Sugar packaging requirements can vary based on customer preferences, regional regulations, and market demands. This calls for packaging systems that are customizable and adaptable to different bag sizes and packaging formats. Nichrome’s bulk bag packing machine offers the flexibility needed to cater to diverse packaging requirements. Whether it is a jumbo bag filling machine or a smaller bag size, the system can be easily adjusted to accommodate various bag dimensions, ensuring the right fit for every packaging need.

4. Streamlining Operations

Efficient operations are crucial for sugar manufacturers to meet production targets and minimize downtime. Nichrome’s bulk bag filling system excels in streamlining operations by integrating various processes into one cohesive packaging system. The sugar packaging system optimizes the entire packaging workflow, eliminating bottlenecks, reducing manual labor, and enhancing overall productivity. This integrated approach minimizes handling time, reduces human errors, and maximizes efficiency, ultimately resulting in cost savings and improved profitability.

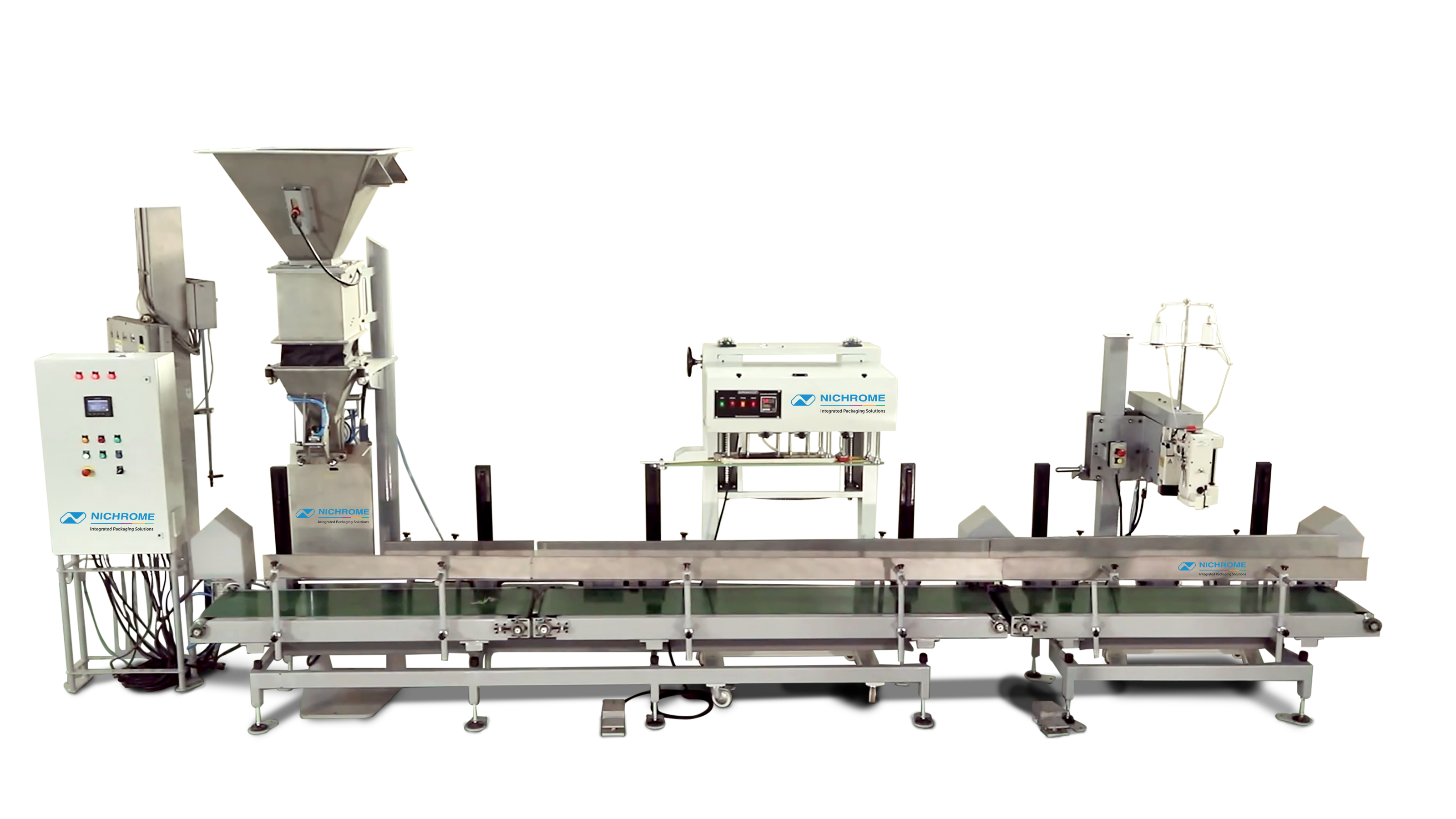

Bulk Bag Filling System by Nichrome

Nichrome, a leading provider of packaging solutions, is proud to present our state-of-the-art Bulk Packing Machine. Specifically designed for packing large bags weighing between 5 to 50 kilograms, this machine is versatile and adaptable to various bag types, including HDPE woven, PP, paper, and valve types. It is the perfect solution for a wide range of products, including rice, sugar, grains, pulses, flour, cake mix, cement, and agro-chemical granules.

Equipped with advanced PLC-controlled technology, our Bulk Packing Machine delivers exceptional output rates of up to 20 bags per minute, ensuring high productivity and efficient packaging operations. Safety is of utmost importance, which is why our machine is equipped with a special ‘no bag no filling’ safety device, ensuring that the filling process only occurs when a bag is present.

With Nichrome’s Bulk Packing Machine, you can expect reliable and consistent performance, enhanced efficiency, and precise packaging for your large bag requirements. The machine’s robust construction and user-friendly interface ensure easy operation and maintenance, allowing you to focus on your production without any hassle.

Embrace the future of large bag packaging with Nichrome’s innovative Bulk Packing Machine. Experience increased productivity, improved product integrity, and optimized packaging operations.

Conclusion:

Let us conclude by saying that Nichrome’s Bulk bag filling for sugar presents its fair share of challenges, from accuracy and efficiency to secondary packaging and customization requirements. However, with Nichrome’s bulk bag filling system and integrated packaging solutions, these challenges are effectively addressed. The advanced bulk bag filling machine, coupled with secondary packaging machines, ensures accuracy, safety, customization, and streamlined operations for sugar packaging needs. Nichrome’s commitment to innovation and providing reliable sugar packaging solutions makes them a trusted partner for the sugar industry.

Experience the efficiency and convenience of Nichrome’s bulk bag filling system for sugar packaging, and witness how it transforms your sugar packaging operations into a seamless and optimized process. Contact Nichrome today to explore their cutting-edge solutions and embark on a journey towards excellence in sugar packaging.

0 comment