Nichrome Milk Pouch Crating System: Multiple Benefits for the Milk Industry

Milk pouches are an integral part of almost every Indian’s morning. We are all accustomed to buying milk in convenient flexible pouches.

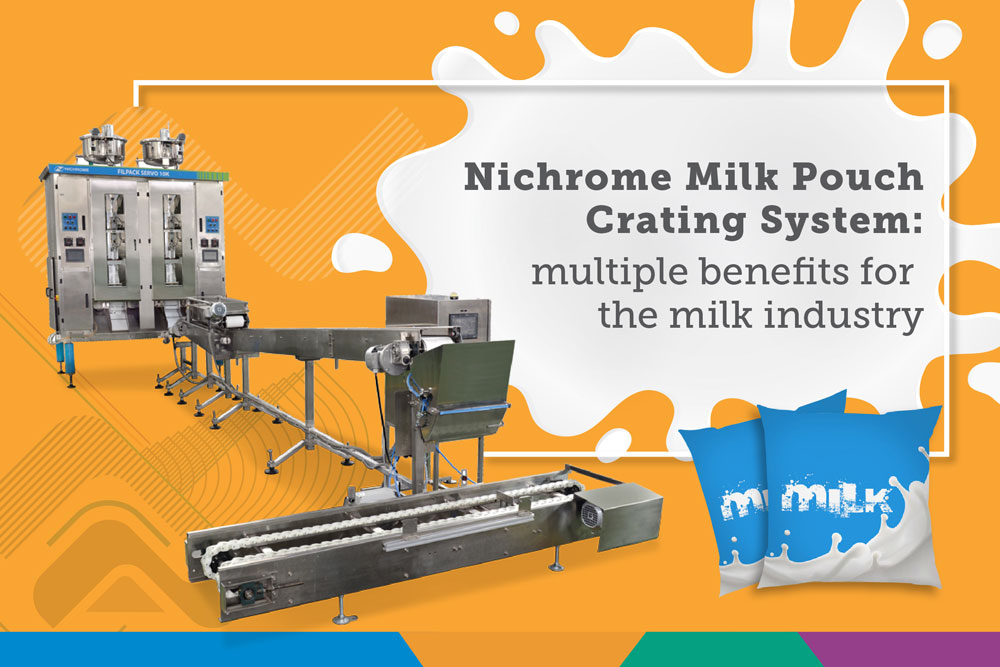

Nichrome is a pioneer in milk pouch packaging, having developed India’s first indigenous milk packaging machine in 1977, to assist in the Govt. of India’s White Revolution initiative. Since then, Nichrome’s automatic milk packaging machines have evolved, and today, the Filpack Servo series of milk pouch packaging machines are market leaders for their speed, accuracy, and reliability.

As flexible milk pouches are not self-supporting, they generally need secondary packaging. Also, as pouches are packed at high speeds by Nichrome’s Filpack Servo range of milk packaging machines, lifting them manually in crates for transportation is not only slow, but could be inaccurate too.

Enter the Automatic Milk Pouch Crating System.

Nichrome’s Automatic Milk Pouch Crating System offers a complementary secondary packaging solution to count & fill pouches in crates in synchronization with Nichrome’s high-speed Filpack Servo machines. The entire process becomes systematic, automated and fast. It helps to maintain quality and food safety standards as well as keep count of the number of pouches and crates.

Nichrome’s Crating system offers many advantages:

• System can be customized as per customer layout and number of machines

• Total end of line solution from crate washing center to cold storage

• Fully automatic so reduces labour

• Provides hygienic and modern secondary packing process

• Improves productivity

• Independent of speed of machines / number of heads

• Independent of volume of pouches

• Each crate is filled with correct pouch count

• System has optional features of data logging and online crate weighing. The entire production data can be logged and saved on Cloud or central server system

The system also offers an optional Online Leak Detection Mechanism whereby each pouch from the pouch take up conveyor passes through a pressing conveyor that removes excess air from leakage pouch through which the operator can easily differentiate leaky pouches.

Furthermore, the Crating System can be customized as per requirements and available space – so customers get a secondary packaging solution tailored for optimization of space, performance and resources.

For more details about the milk pouch crating system, or other cutting-edge integrated packaging solutions, contact www.nichrome.com

0 comment